Metalwork

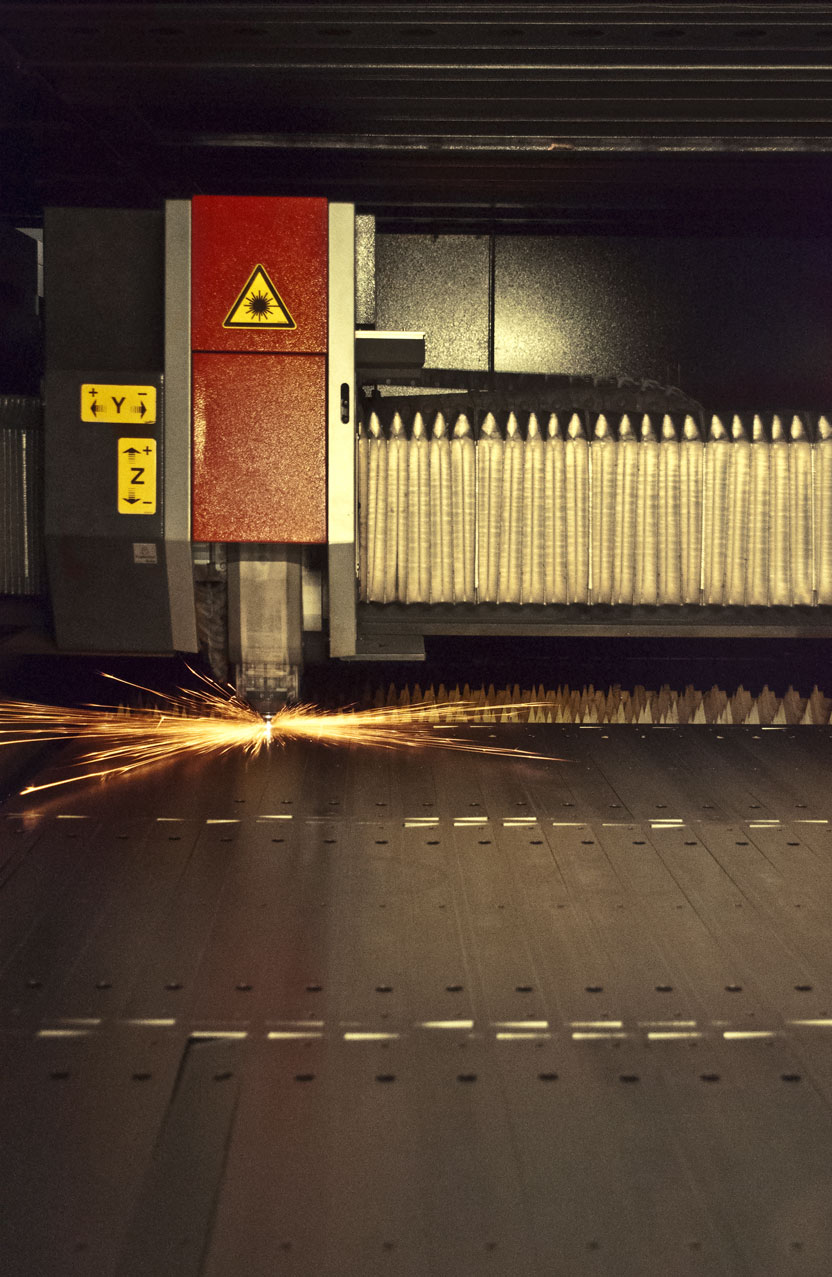

Cutting the sheet metal is the first step in all processing.

We offer our customers all possible sheet metal cutting processing by using laser technologies and cutting-edge machinery.

In 2009, we decided to adopt fibre optic laser cutting and we were one of the first ones in Italy to do so. In 2014, we introduced the latest jewel in the sector’s crown, which allowed us to increase the quality of our processing even further while cutting times.

We combine these laser technologies with punching machines featuring automatic tool changes to make work even easier and eliminate machine set-ups.

Thanks to the innovative technologies which we decided to use, we can offer three types of punching:

> Laser cutting + punching

> Punching with angle shears to increase productivity

> Punching with automatic tool changes so there is practically no machine set-ups

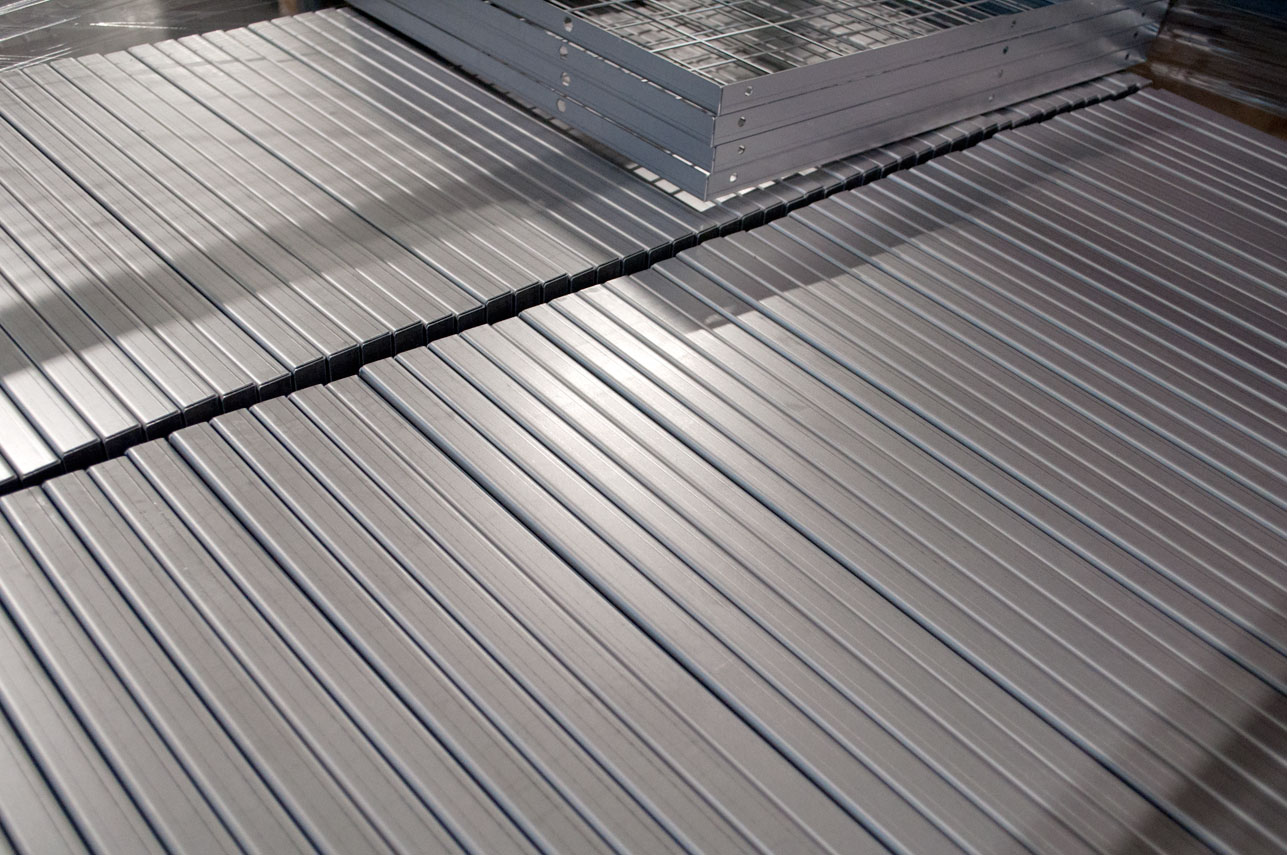

All our machines are also equipped with automatic loading and unloading to cut processing times and to give our customers the best quality more quickly.

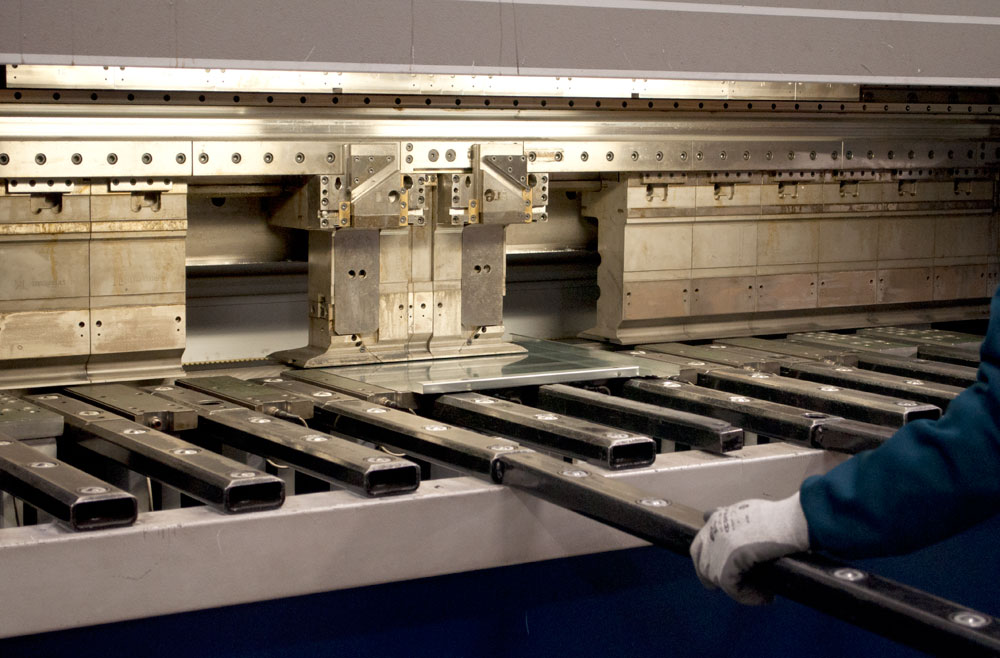

Over the years, we also developed all the possible technologies in our sheet metal bending department.

Starting from classic manual bending, using various hydraulic press brakes, we integrate manually controlled electric press brakes, panelling technologies using three panelling machines with semi-automatic installations, right up to the most advanced automation formed of four bending robots.

Our experience has also led us to add various tools and equipment purchased for each customer to carry out specific processing.

Tecnology

FIBER LASER WITH AUTOMATION AND INTEGRATED WAREHOUSE

PUNCHING MACHINES

COMBINED PUNCHING MACHINE + LASER

AUTOMATED BENDING ROBOT

PANEL MACHINES

MANUAL BENDING MACHINE